The MGA With An Attitude

PACKING BETWEEN THE BODY AND FRAME - RT-103

At 02:19 PM 5/12/03 -0400, Gary Fischer wrote:

>"I am trying to determine the locations of the packing that is supposed to go between the frame and the inner rockers at the doors. This is inside the cockpit and seals the gap between the frame and the body."

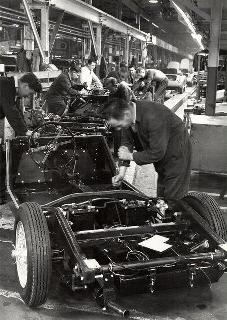

Okay, we're here in the Restoration section, but in fact a lot of the required weather seal packing is spread around in other tech areas. During a full restoration with the body off, before installing the body on the frame you should check the Frame Repair tech section for frame welding repairs and installation of the center tunnel and floorboards, all of which is more conveniently done before body mounting. There is considerable attention required to packing and sealing the tunnel and floor. The rear vertical floorboard in particular needs to closely match the contour of the battery cover.

Note: Cork under the boot floor is not shown in the Service Parts List. Note: Cork under the boot floor is not shown in the Service Parts List.

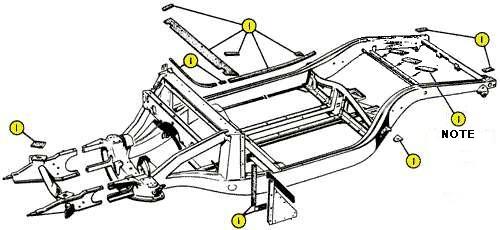

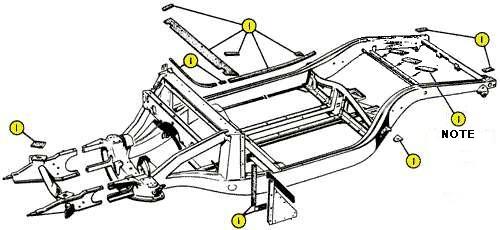

The body sits on top of the frame, and the packing goes in between body and frame at points of contact. It should run below the door openings and also forward up the angled rails to the top, and behind the door openings up the angled rails as far as the battery cover position (front edge). This packing should be a piece of closed cell foam rubber about 3/8" thick. Place this on top of the frame on the outer half of the width of the frame rail outboard of and up against the center weld ridge. It may be single sided sticky, or glue it in place on the frame if necessary. No need to glue it on the top surface (body side).

( Click for larger image, or print for higher resolution. )

The top of the frame goalpost (under the heater shelf) gets covered with cork about 1/8" thick (maybe a little thinner). The top of the frame goalpost (under the heater

shelf) gets covered with cork about 1/8" thick (maybe a little thinner). Glue that to the frame also. Ideally the cork and foam rubber should abut with no gap. More likely you may have to put small strips of foam rubber at the ends to close the gap. There should also be cork packing at the four pads which accept larger bolts near the door openings, two ahead of the door inside the cockpit, and two behind the door openings outside of the main frame rail accessible from underneath (or in the front area of the rear wheel well). No seal is required here, but use the same cork material to make up the same thickness regardless, and also to eliminate any squeaks which might be caused by relative motion between frame and body. Also place four more cork pads on top of the frame, two at the extreme rear of the frame under the boot floor, and two on top of the front frame extension under the body horizontal air pan ahead of the radiator. There is also a row of four bolts across the boot floor just aft of the rear axle, so that frame cross member should have cork on top as well.

shelf) gets covered with cork about 1/8" thick (maybe a little thinner). Glue that to the frame also. Ideally the cork and foam rubber should abut with no gap. More likely you may have to put small strips of foam rubber at the ends to close the gap. There should also be cork packing at the four pads which accept larger bolts near the door openings, two ahead of the door inside the cockpit, and two behind the door openings outside of the main frame rail accessible from underneath (or in the front area of the rear wheel well). No seal is required here, but use the same cork material to make up the same thickness regardless, and also to eliminate any squeaks which might be caused by relative motion between frame and body. Also place four more cork pads on top of the frame, two at the extreme rear of the frame under the boot floor, and two on top of the front frame extension under the body horizontal air pan ahead of the radiator. There is also a row of four bolts across the boot floor just aft of the rear axle, so that frame cross member should have cork on top as well.

On the sides of the frame, just aft of the goalpost, there are triangular cover plates formed in thin aluminum. These were originally packed around the back and bottom edges with moderately thick strips of felt (or horsehair). I tend to dislike this material as it can trap and hold moisture for extended periods of time while promoting rust. Better to use a closed cell foam rubber, perhaps 1/4 inch thick, similar to the packing on top of the frame under the door. Or in a pinch you might caulk these frame closure panels in place, figuring these panels might never be removed again after a full restoration. A cork packing strip at the front edge of the closure plate goes on the outboard side of tte plate (after plate screws are installed). This cork strip is for packing between the frame and body.

There should be a battery cover seal, a thick mounded rubber piece, that runs across the top of the rear vertical floorboard. Staple this through the top, leaving the rubber bead hanging over the front edge of the board. Also glue it in place if you prefer. The ends of this rubber piece should extend all the way to the ends of the board, effectively tucked underneath the body sheet metal for an inch or two at each side, hopefully abutting the foam strips on the side rails with no gap. You might be able to squeeze the battery cover seal under the body at the ends after the body is in place, but probably easier to install this piece before the body goes on.

With all packing in place there should be a continuous seal all around the cockpit, cork across the front, foam rubber along the sides, and mounded rubber across the back. This is all that was used by the factory.

However, .... I can tell you by practical experience that this may not make a total seal at the back of the frame to either side of the battery cover opening. When driving in continuous rain I have had water splash from the rear tires on top of the frame and run forward by gravity to encroach under the body metal either side of the battery cover area behind the doors. The water may be sufficient to completely soak the carpeting, starting with the area of the door sill and proceeding under the seats and into the foot well area. At one time I had a duffle bag with clothes setting in the passenger side footwell during a long trip in the rain, and the bag got saturated with at least 10 pounds of water.

I think this problem is caused by poor fit of the body against the frame in the area behind the door opening. The solution for this is to put a VERY THICK bead of caulking on top of the frame starting a few inches aft of the door opening where the frame starts to angle upward. Position the caulking bead on top of the foam strip, just about down the center of the strip, continuing all the way to the rear edge of the strip and then in towards the center of the car to the edge of the battery cover opening (or to the end of the molded rubber cover seal). Test fitting the body on top of the new seals may reveal where you need to install this caulking. Trying to inject caulking into this area with the body in place is very difficult because of limited access from underneath.

|

Here is a picture of an original rubber seal. It is impossible to determine the original cross section from condition of the 55 year old rubber.

Image immediate right is from the Service Parts List,

showing a thick rubber seal with a slot that will accept the front lip of the body fixed battery cover panel.

showing a thick rubber seal with a slot that will accept the front lip of the body fixed battery cover panel.

Addendum:

See more notes and photos on body to frame packing in article RT632.

|

showing a thick rubber seal with a slot that will accept the front lip of the body fixed battery cover panel.

showing a thick rubber seal with a slot that will accept the front lip of the body fixed battery cover panel.